Exactly How Membrane Layer Changes Add To the Longevity of Electronic Control Panels

Membrane layer switches play an important function in improving the longevity of electronic control panels, primarily through their multi-layered construction which supplies reliable protection against ecological elements such as dampness and dirt. The lack of moving components considerably reduces the probability of mechanical failings, making membrane layer changes perfect for requiring applications.

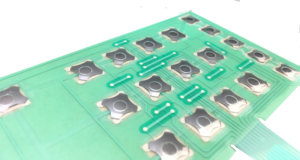

Definition of Membrane Layer Buttons

Membrane switches are created to be slim and lightweight, making them appropriate for applications where area is restricted. They can be made in various shapes, sizes, and colors, using adaptability in layout that meets aesthetic and useful demands. Additionally, membrane layer buttons can include various technologies, such as responsive responses and LED indications, boosting customer experience.

As a result of their building and construction, membrane switches are frequently resistant to dust, moisture, and general wear, contributing to their toughness in requiring settings. Their smooth style not only assists in very easy cleansing however likewise reduces the danger of mechanical failure, making them a favored choice for producers seeking reliable interface in their digital control panels.

Security Versus Ecological Factors

The layout of membrane switches over inherently gives a level of protection against numerous ecological aspects, which is important for maintaining performance in difficult conditions - Membrane Switch. These buttons are commonly built with layers of flexible products that secure inner elements from moisture, dirt, and pollutants. By enveloping the circuitry, membrane switches over reduce the risk of brief circuits and corrosion, which can dramatically harm performance

Moreover, making use of robust adhesives and sealers during production enhances their resistance to ecological challenges. Membrane layer switches can sustain exposure to chemicals and solvents, making them suitable for sectors such as food processing and medical care, where hygiene and sanitation are critical. Their smooth surface layout likewise prevents the build-up of dust and microorganisms, facilitating easier cleansing and upkeep.

Temperature variations are another environmental concern, and membrane buttons are crafted to function properly across a vast array of temperature levels (Membrane Switch). This adaptability guarantees that control board remain operational in numerous settings, from industrial atmospheres to customer electronic devices

Influence On Customer Communication

User interaction with electronic control panels explanation is dramatically influenced by the design and capability of membrane buttons. These buttons supply a tactile interface that improves the overall customer experience, permitting instinctive navigation and control. Their responsive nature ensures that users obtain immediate comments upon activation, which is vital for jobs needing accuracy and efficiency.

Furthermore, the smooth surface area of membrane changes facilitates easy cleaning and upkeep, promoting user confidence in the integrity of the user interface. This cleanliness is specifically essential in settings where hygiene is paramount, such as medical or food handling settings. Additionally, the small and lightweight design of membrane layer switches adds to the visual appeal of control panels, encouraging individual involvement with a modern and smooth look.

Additionally, the integration of visual elements, such as printed icons and backlighting, assists users rapidly recognize functions, minimizing the finding out contour connected with brand-new devices. Because of this, individuals can operate devices better, resulting in enhanced productivity and complete satisfaction. In summary, membrane layer switches play a pivotal function in improving individual communication by combining capability, aesthetics, and simplicity of usage, ultimately bring about improved functional performance.

Design Versatility and Customization

Layout flexibility and personalization are vital facets of membrane layer buttons, allowing makers to tailor digital control board to details applications and individual demands. This versatility enables the integration of different layout components, such as colors, graphics, and appearances, which can enhance the aesthetic allure and customer involvement of the control board.

Membrane layer switches can be customized in size and form, suiting a large range of tools and applications, from commercial machinery to customer electronics. This versatility ensures that suppliers can produce intuitive interfaces that line up with individual expectations and operational demands. Additionally, the ability to include one-of-a-kind features such as backlighting or tactile responses further boosts functionality, enabling a more interactive experience.

In addition, the manufacturing procedure for membrane switches over sustains the fast prototyping look here of layouts, allowing makers to iterate and refine their principles quickly. This ability not only accelerates the development timeline yet likewise makes certain that the last item fulfills certain practical and visual criteria.

Cost-Effectiveness and Longevity

Cost-effectiveness and long life are substantial advantages of membrane buttons, making them an appealing choice for producers and end-users alike. These buttons are usually cheaper to produce than conventional mechanical switches, mainly because of their simplified manufacturing processes and the minimized variety of components needed. This cost benefit extends not just to preliminary production however additionally to long-lasting operational expenditures, as membrane switches usually need much less maintenance and have a lower failure price.

Moreover, the longevity of membrane switches contributes to their total value. Built from sturdy materials, they are resistant to ecological aspects such as dampness, dust, and chemicals, which can bring about early wear in other switch kinds. The absence of moving components lessens mechanical failing, permitting membrane layer switches to preserve functionality over expanded durations.

This resilience is particularly useful in applications needing constant performance under requiring problems, such as clinical devices and industrial devices. Inevitably, the mix of cost-effectiveness and longevity makes membrane layer switches over an economically feasible selection for suppliers, supplying dependable options that withstand the test of time while enhancing budgetary considerations.

Final Thought

In final thought, membrane layer buttons considerably improve the durability of electronic control panels with their durable building and construction and protective attributes. By effectively securing circuitry from ecological dangers and reducing the danger of mechanical failing, these switches make certain consistent performance sought after applications. The seamless layout advertises hygiene and ease of maintenance, while personalization alternatives make it possible for tailored options for different requirements. Generally, membrane layer changes stand for Clicking Here a reliable and affordable choice for improving the longevity and functionality of digital control systems.